BONDLESS PRECSION WAFER STACKING

Temporary bonding are used by mid-end processing manufacturers to handle thinned wafers. But it has limited temperature budget and the chemical some time can cause yield issues.

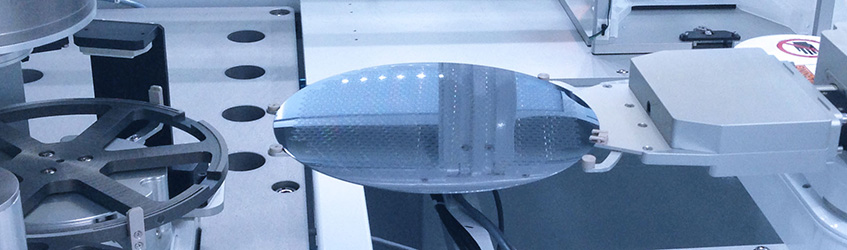

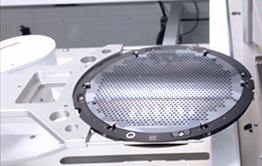

Quartet Mechanics offers MEMS (Microelectromechanical systems) manufacturers’ mid-end processing a wafer vehicle free from the traditional chemical bonding. This novel mechanical-based fragile wafer stacking solution features high precision alignment (± 5 µm); high yield is reached with its intelligent vision-guided robotic transferring and fixturing that prevents damage of delicate thin, warped or perforated wafers.

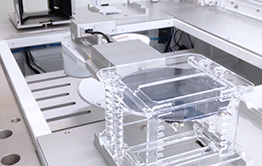

Cost effective fully automated wafer alignment and insertion of wafer or wafers stacks into fixturing for paste dispensing, low temperature bake, deposition processes and wafer dicing.

While fixturing is not allowed for processes such as high temperature bake and etch processes specialized robotic end effectors load wafer stacks to quartz boats for bake or etch operations while maintaining alignment.